Known as PTC, Positive Train Control is a complex signaling and communications technology that is designed to make commuter rail even safer.

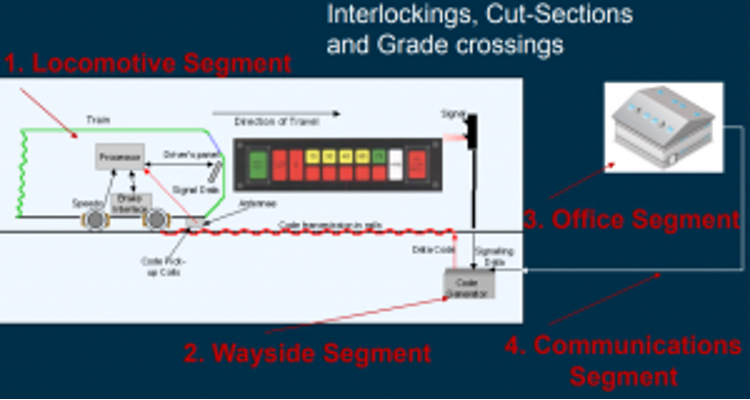

PTC is a communications-intense technology that transmits data between trains and communications towers using wireless Internet, GPS, and encrypted radio transmissions. It requires thousands of sensors on train tracks and locomotives; data centers to collect and analyze the data, and a train’s engine and braking system to be optimized as needed.

PTC utilizes a series of sensors and integrated monitoring systems that track key movements of trains and conditions on rail tracks in real time to identify potentially hazardous situations. If an unsafe speed situation arises, PTC automatically will trigger a train’s braking system to slow it or stop it and prevent an accident, such as a train-to-train collision.

Commuter rail operators are continuously updating these systems and their components to ensure safe, reliable, quick, and convenient commuter rail service.

Traveling by commuter rail and intercity rail is 18 times safer than traveling by automobile. And PTC is making commuter rail and intercity rail even safer.

For commuter rail operators and the entire public transportation industry, safety is our first priority. Safety is not simply a value we share; it is a core operating principle and a promise to our riders. Commuter railroads work every day to continuously make safety improvements and constantly re-evaluate safety procedures as well as reinforcing a safety culture with employees.

Commuter and intercity rail have 0.36 passenger fatalities per billion passenger miles, compared with 6.53 passenger fatalities for automobiles or light trucks. citation

PTC is a technology that overlays with existing safety and signaling systems and is designed to prevent:

- Train-to-train collisions;

- Over-speed derailments;

- Incursions into established work zone limits; and

- The movement of a train through a mainline switch in the improper position.

While Positive Train Control prevents many types of incidents and will make our safe systems even safer, PTC does not prevent the following:

- Grade-crossing collisions;

- People trespassing on track;

- Track or train defect derailments;

The estimated cost to operate and maintain PTC is up to $130 million per year. The implementation of PTC cost over $4.1 billion and, though mandated by Congress, the state and local governments shouldered the bulk of the installation costs. The implementation cost of PTC and the annual costs of operating and maintaining PTC come on top of the existing $100 billion backlog needed to bring the national public transportation industry into a state of good repair. This is a major challenge for publicly funded transit systems in dire need of upgrades.

There are 30 commuter railroads currently in the United States.

The method of PTC operation depends on the variant of PTC installed. Three major variants for PTC are described below:

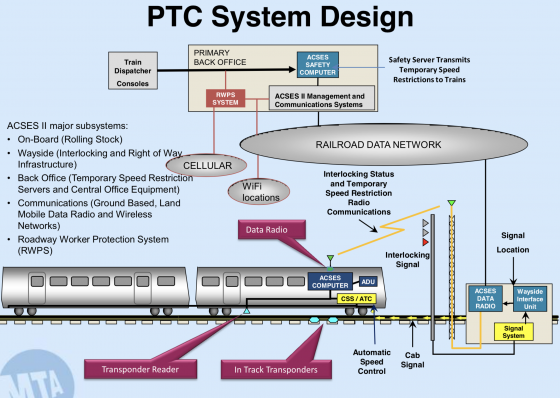

ACSES

Advanced Civil Speed Enforcement System, (ACSES) is unique among PTC options as it is a vital rather than a non-vital overlay. First deployed on the Northeast Corridor in the 1990s, ACSES has been approved in a variety of different configurations throughout the Northeast. ACSES is also unique among PTC options in that it is transponder-based. The basic package functions as an overlay interfacing with an Automatic Train Control (ATC) system consisting of a Cab Signaling System (CSS) and a Speed Control System (SCS).

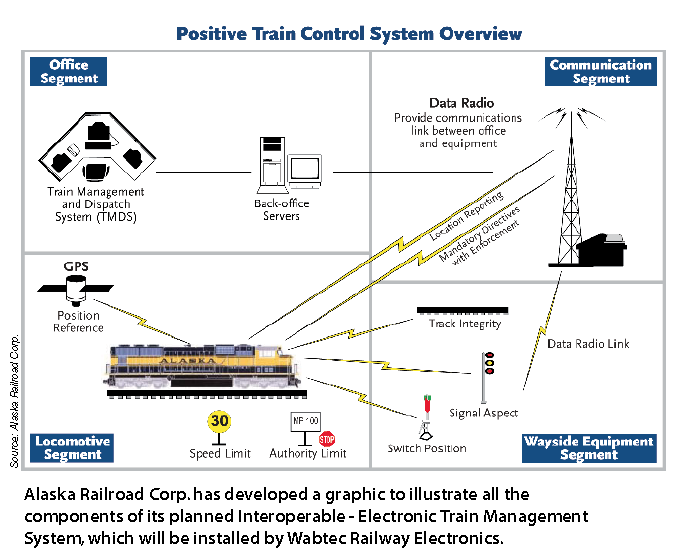

I-ETMS

Formerly known as Vital Electronic Train Management System, I-ETMS, or Interoperable Electronic Train Management System, is the second iteration of a PTC system originally pioneered by the former Burlington Northern Railroad on one of its single-track lines in Illinois used primarily for coal and grain traffic. This GPS and communications-based version of PTC was what was originally called for in the PTC mandate and has been the system of choice for at least five of the seven class-one freight railroads.

E-ATC

Electronic Automatic Train Control, (E-ATC) is the system of choice for most of the smaller commuter operations that do not run on Class I railroads. This is not interoperable with the Class I railroad systems, requiring dedicated equipment for its use.